Final Project

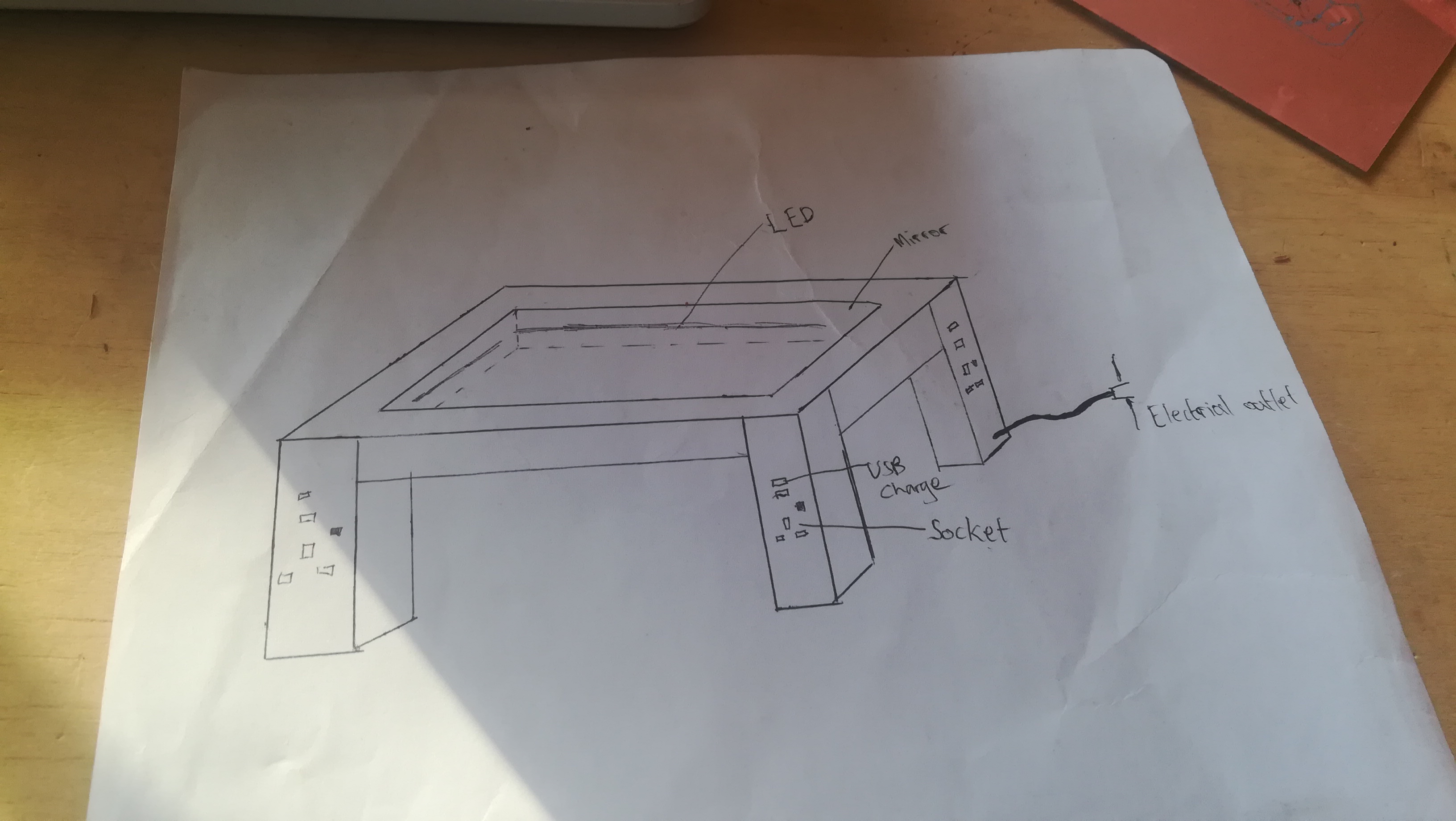

My final project idea is based on a smart coffee table, the table will have an infinity mirror at the top which will comprise of mirrors and an LED strip that is built from scratch with its controller. The legs of the coffee table will also have power outlets for charging phones, laptops and other devices.

The Idea for this table came about when i noticed in many house holds power outlets are either at specific walls of the living room while the sitiing arrangement is different therefore cables run all over when someone wants to charge any device this creates room for accidents easily as one can trip, or plug out a cable forcefully when they trip and either damage the device or the cable.

The Idea for this table came about when i noticed in many house holds power outlets are either at specific walls of the living room while the sitiing arrangement is different therefore cables run all over when someone wants to charge any device this creates room for accidents easily as one can trip, or plug out a cable forcefully when they trip and either damage the device or the cable.

The solution of using the coffee table as an interactive power outlet is because many living rooms have their chairs arranged in a manner to surround the coffee table at the center therefore if each leag of the coffe table had a power outlet and the coffee table had only one cable to the power outlets at the wall chances of accidents are drastically reduced within the household.

Distributing the power outlets will also prevent congestion at the source.

The solution of using the coffee table as an interactive power outlet is because many living rooms have their chairs arranged in a manner to surround the coffee table at the center therefore if each leag of the coffe table had a power outlet and the coffee table had only one cable to the power outlets at the wall chances of accidents are drastically reduced within the household.

Distributing the power outlets will also prevent congestion at the source.

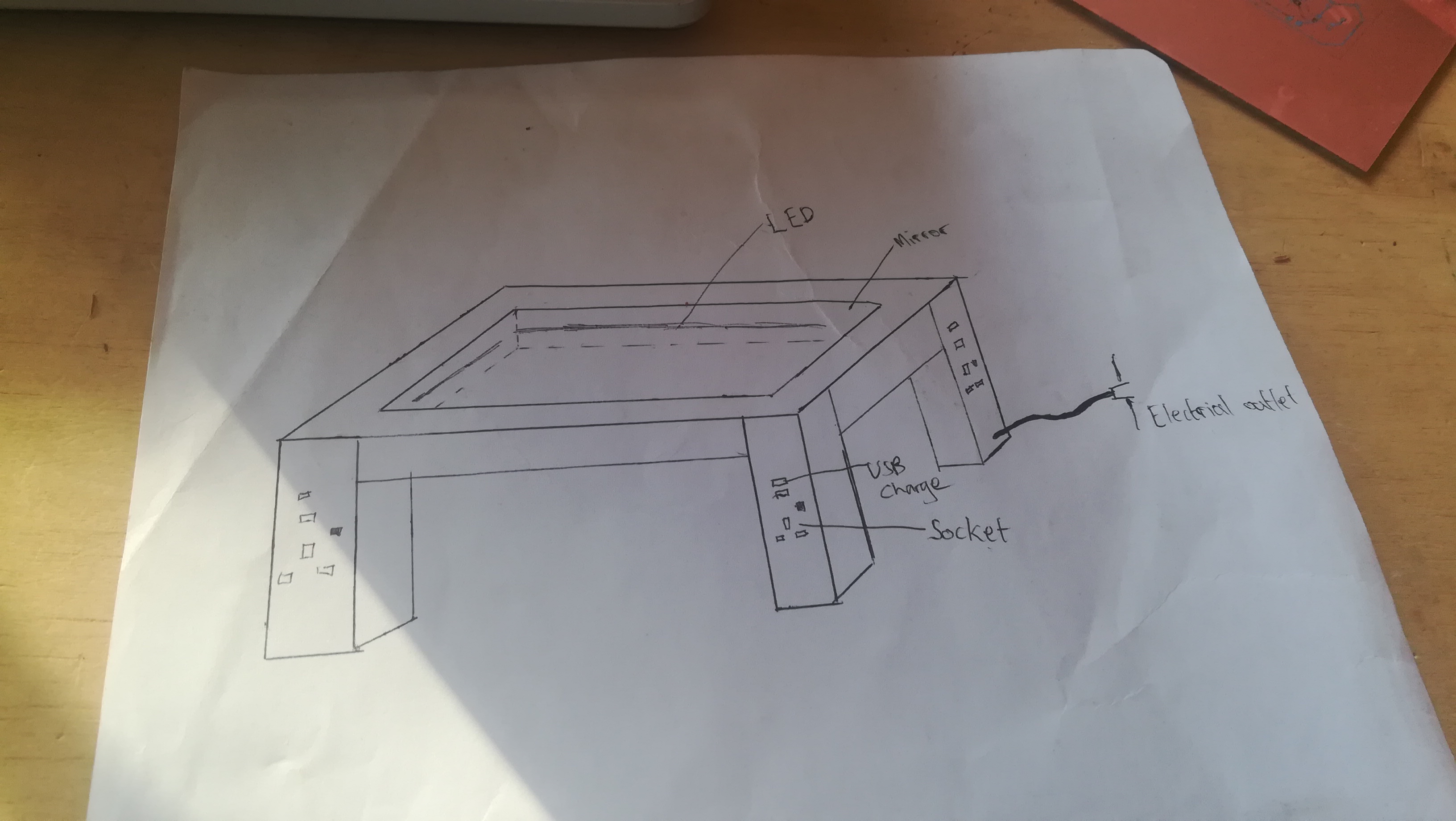

The sketch of the final project is as follows:

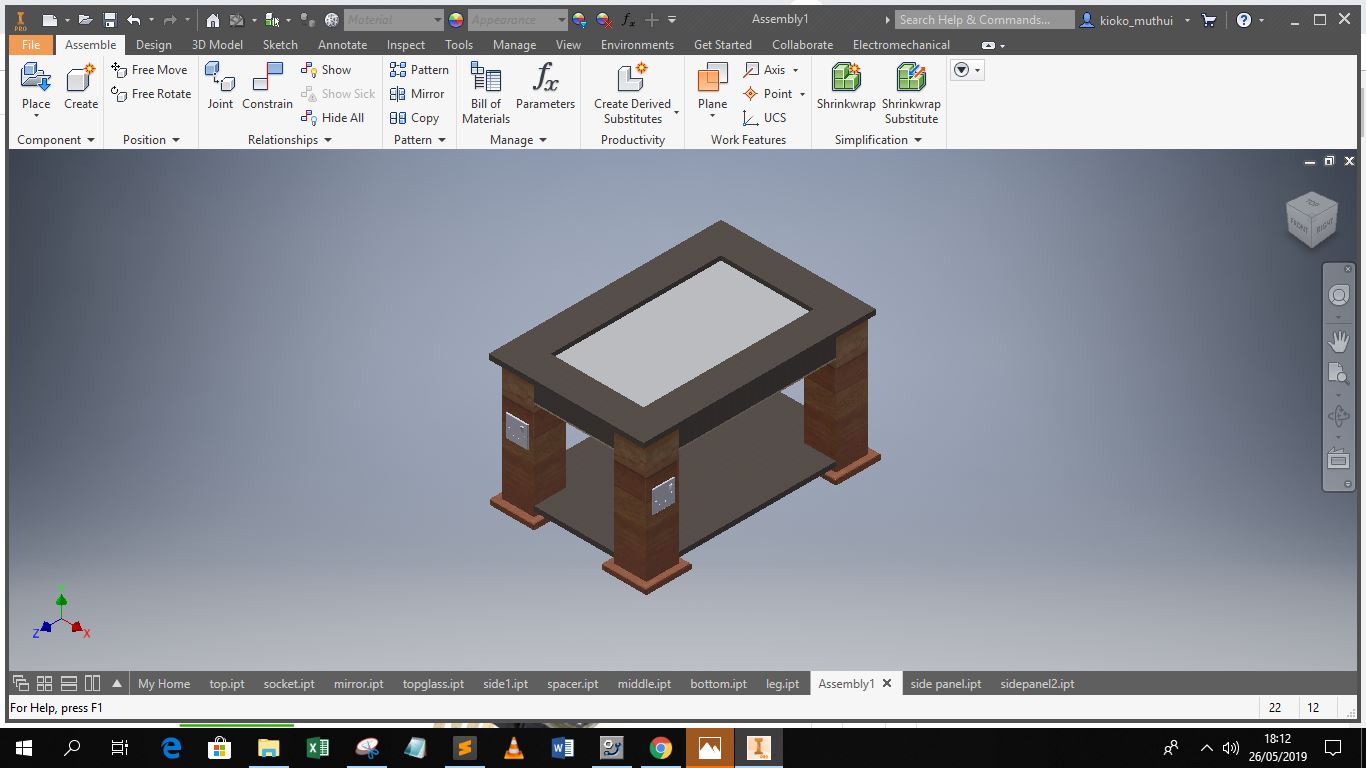

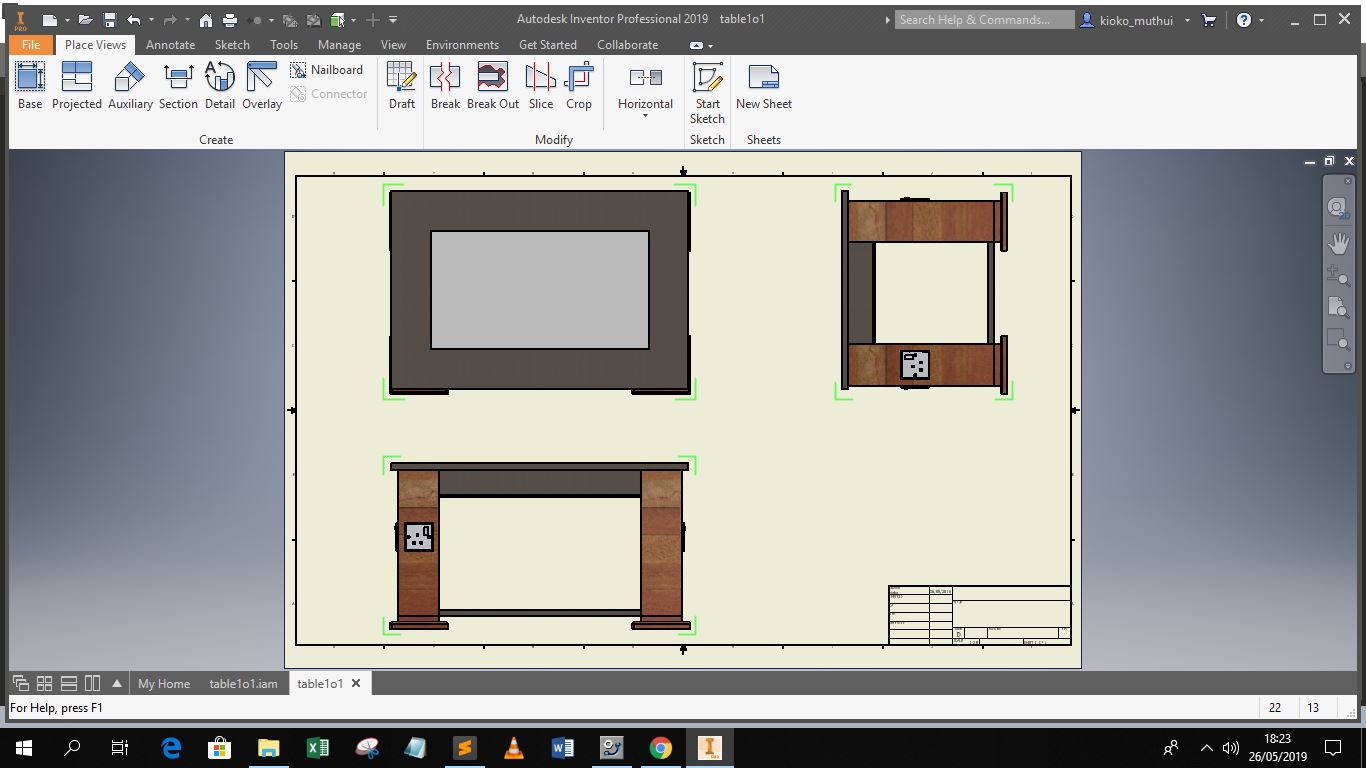

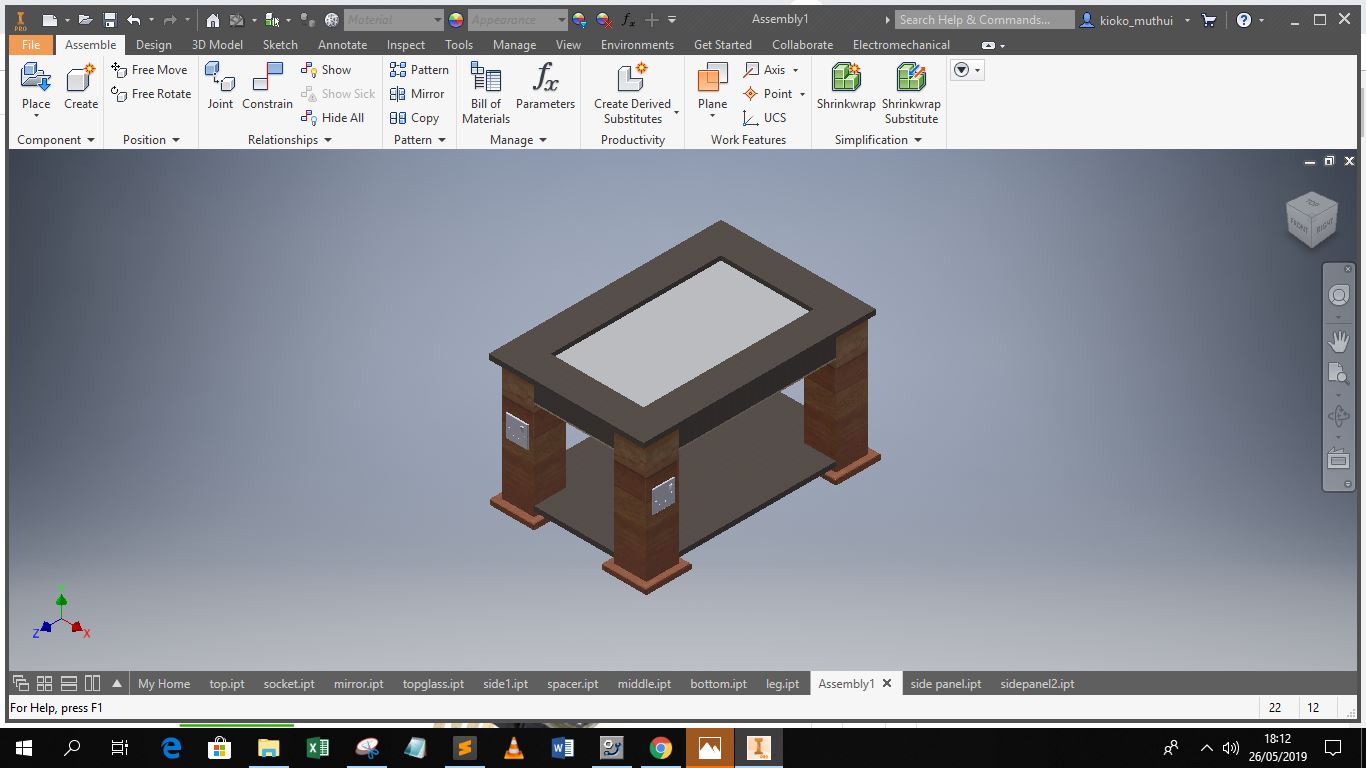

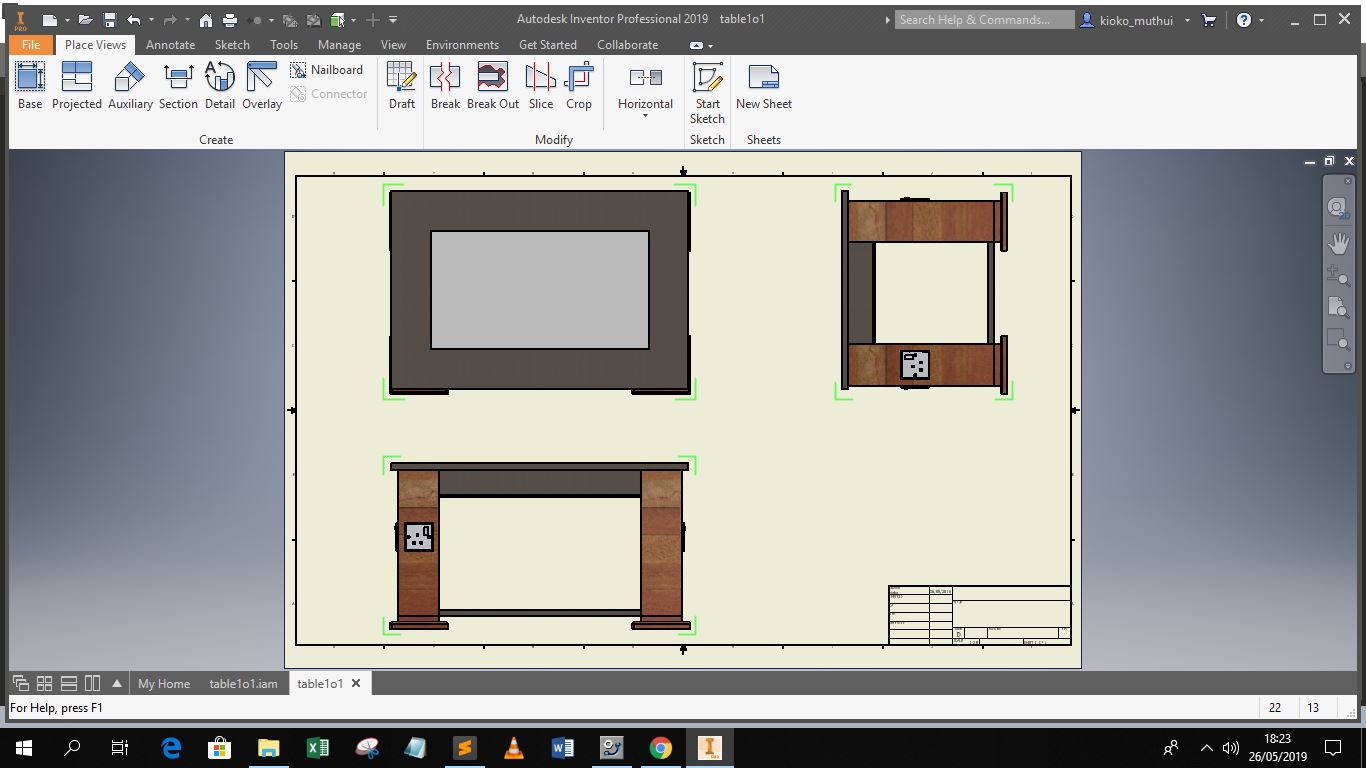

The 3D design was developed using inventor for the complete design process. Kindly go to my Week 3 Page

Download the CAD files Here

Before moving to production the next stage was to create my Bill of Materials for the tables structure which is as follows

- 4ft by 8ft by 0.75" Block board

- 2.5" wood screws 1 packet

- 1" wood screws 1packet

- Mirror 40cm by 60cm

- Clear Glass 74.6cm by 64.6cm

- solar film 1m by 1m

- 4 Sockets

- 2" by 2" timber 4ft

- Black spray paint

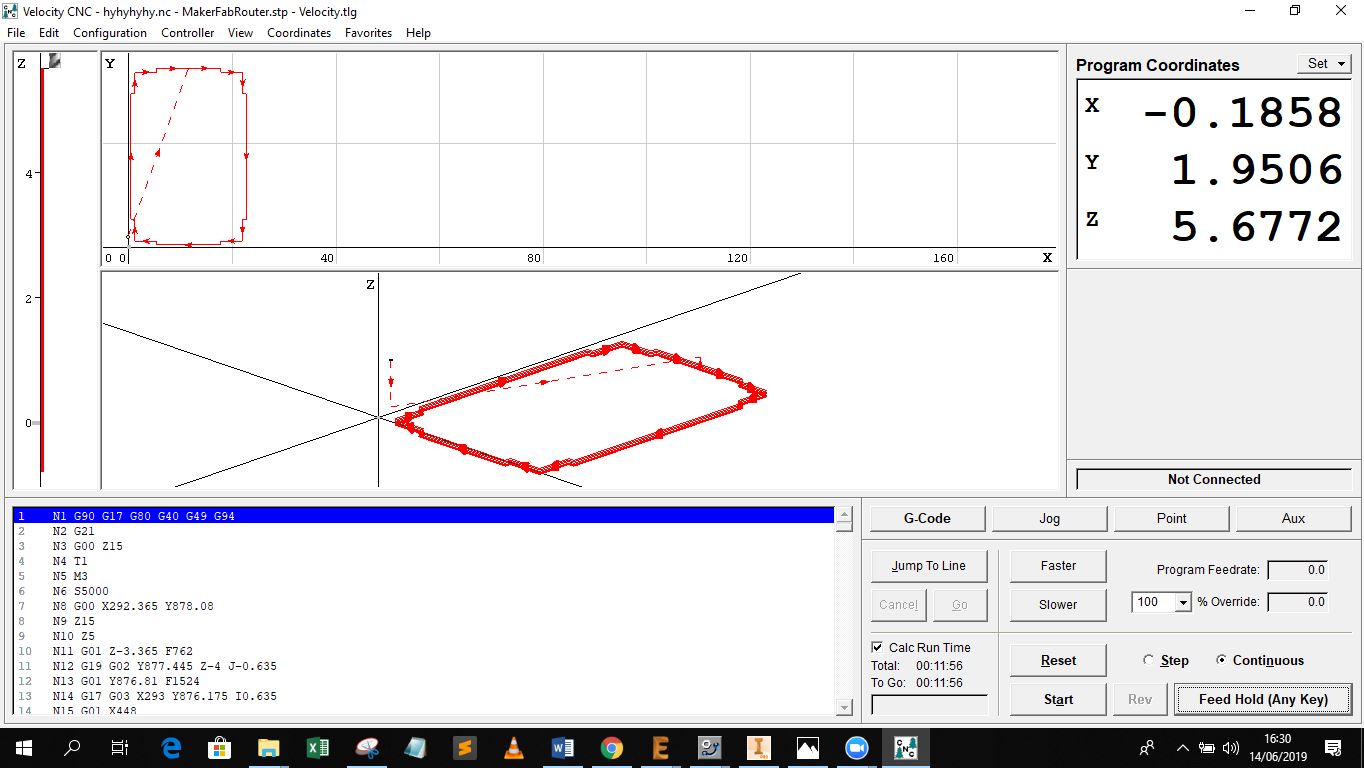

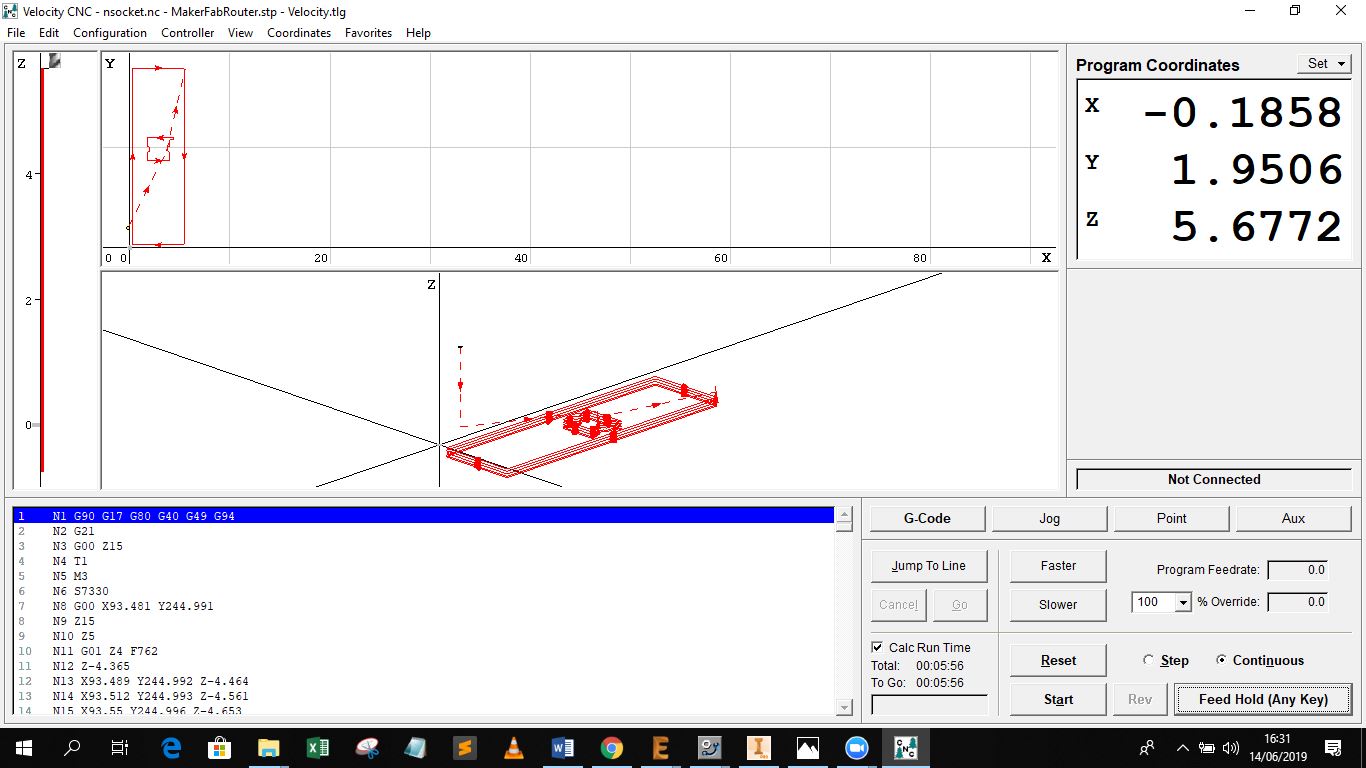

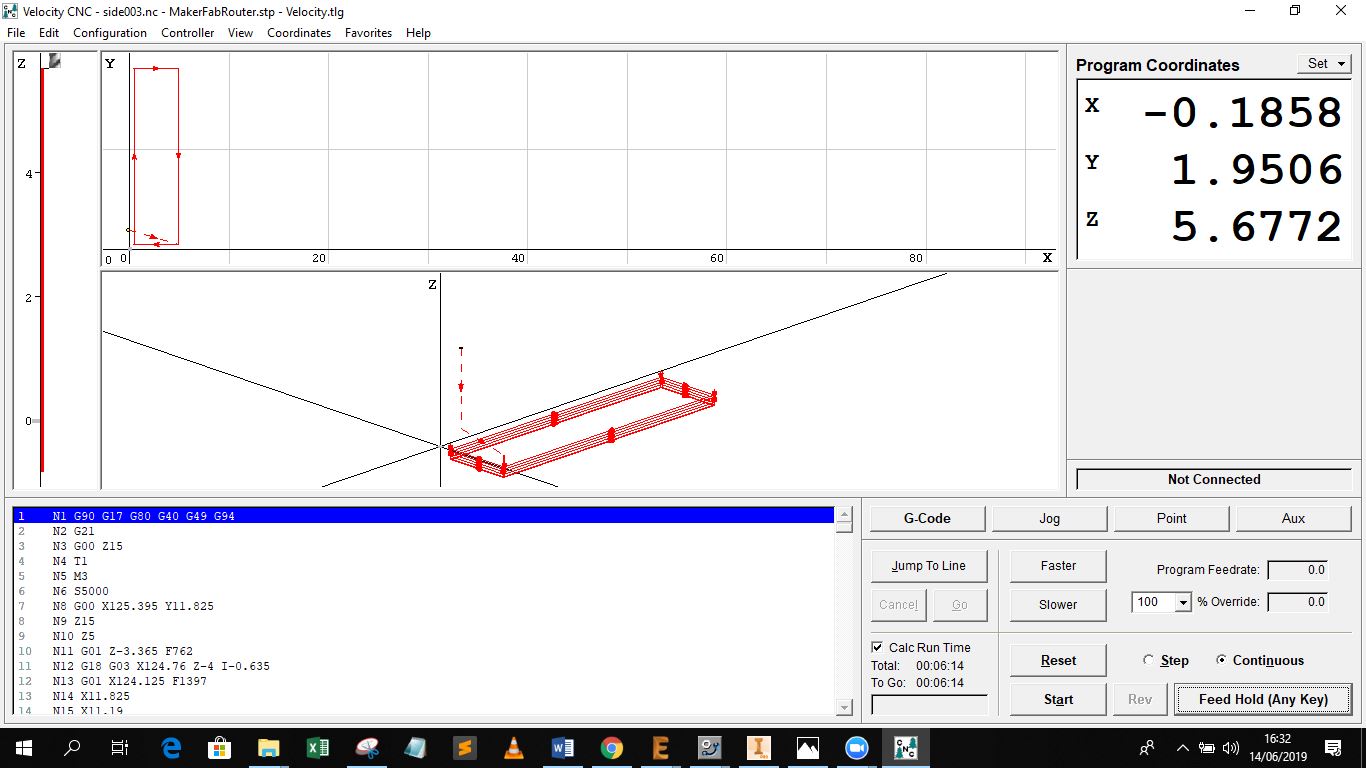

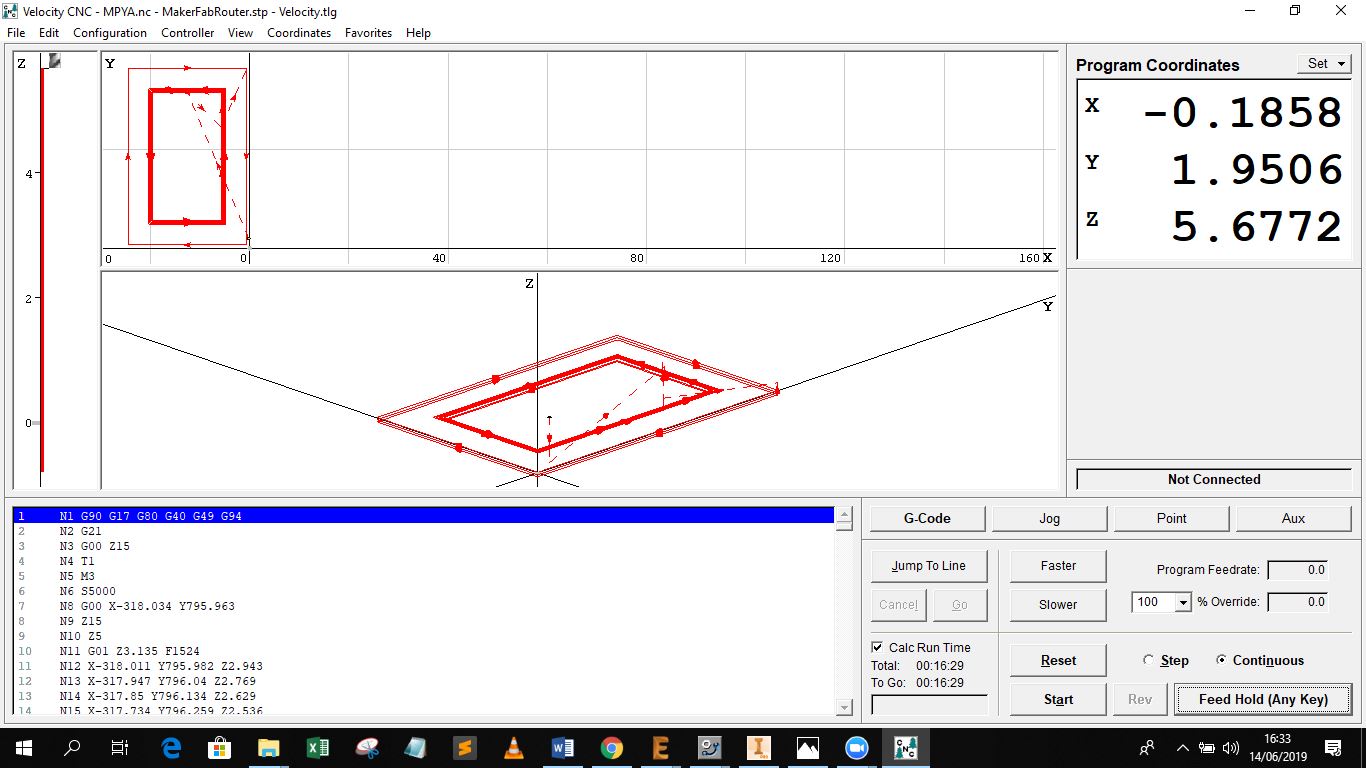

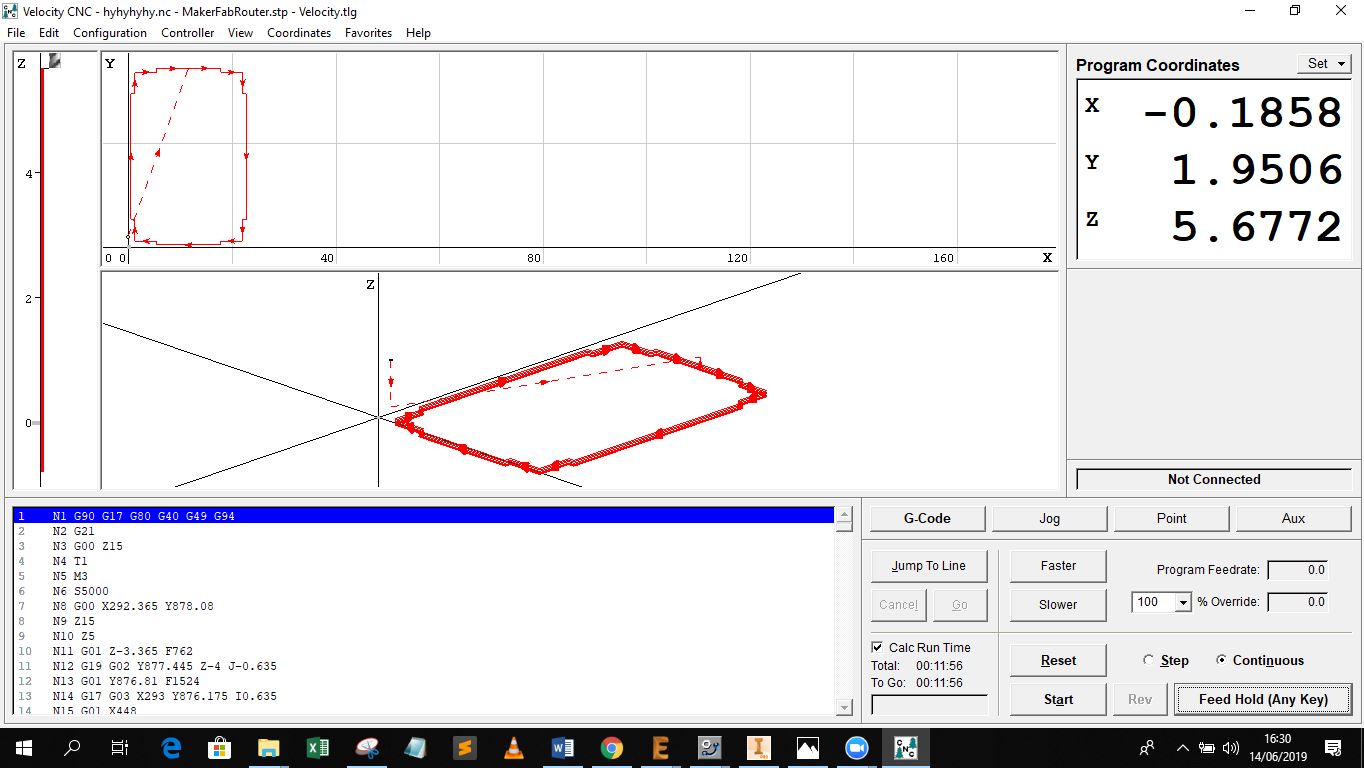

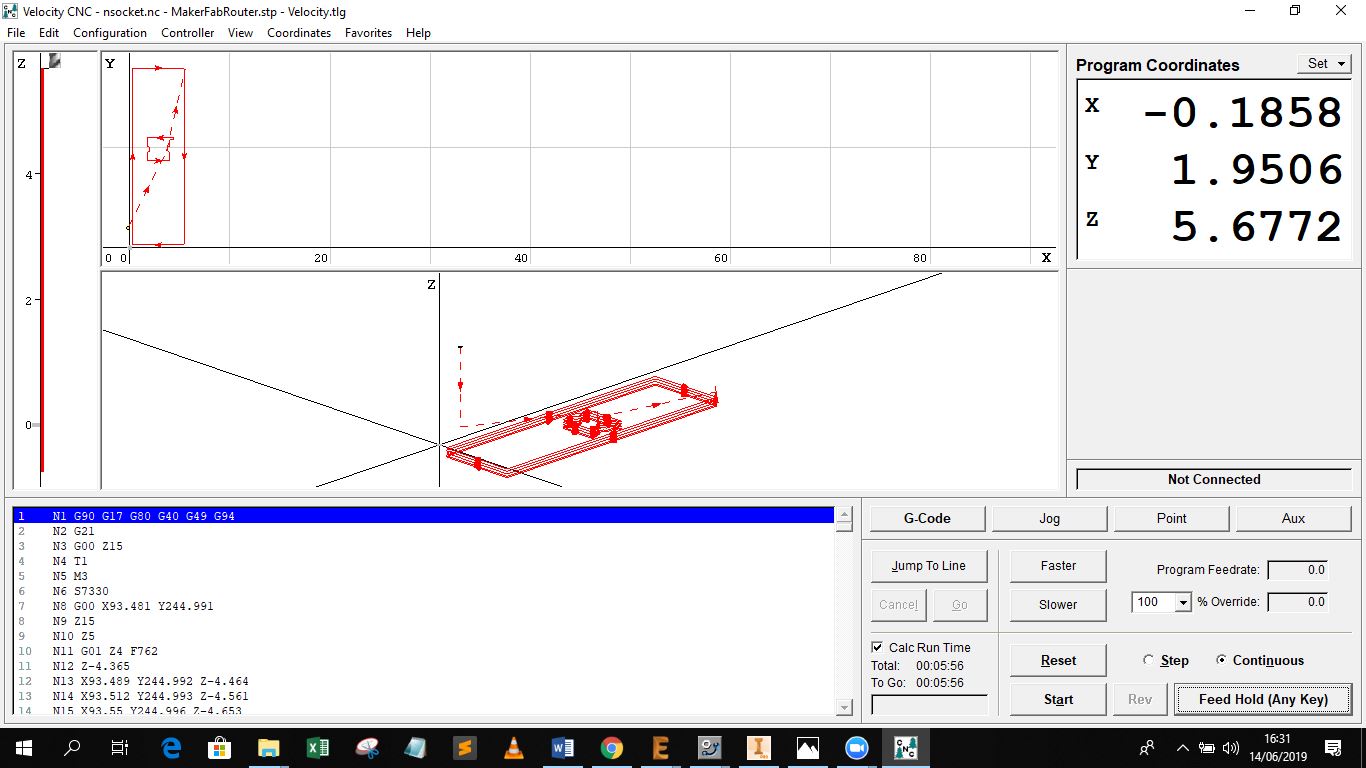

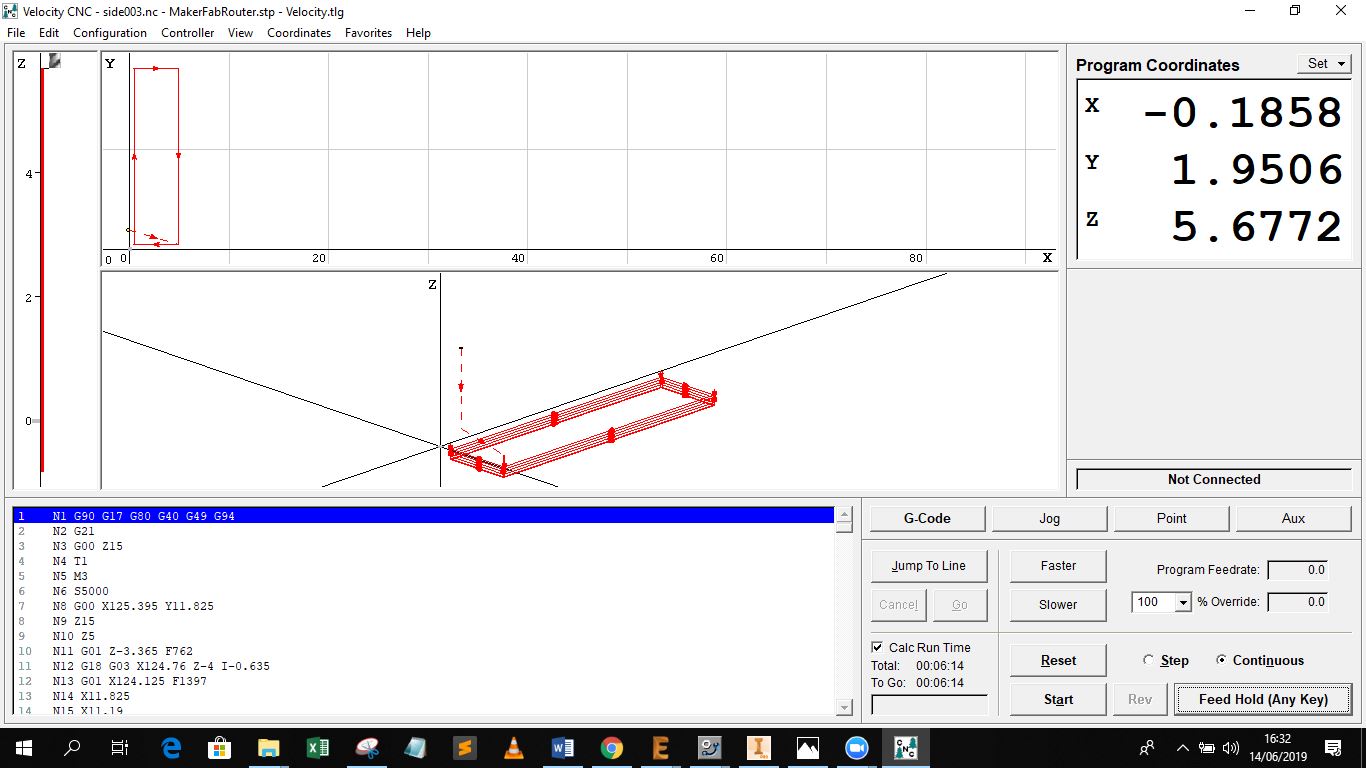

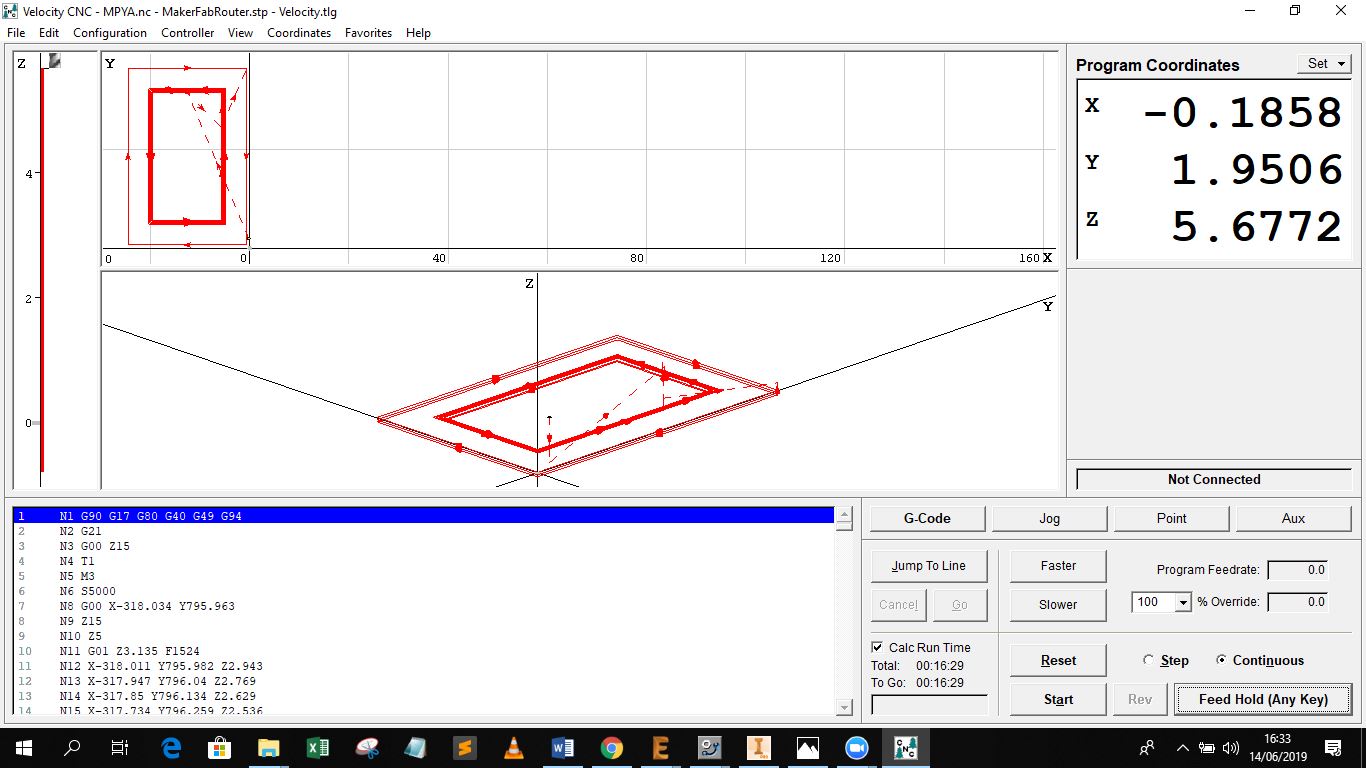

After acquirng the components the next stage was cutting out the different parts and assembling them together. I used A CNC to cut out the different parts. The best thing about it is that i generated the GCODES for machining from the Design Software i used for CAD thus i could easily modify parts as I progressed in machining, Below is the interface i used in machining which is the Velocity CNC however gnerating the G codes was done using the HSM utiliti in Autodesk Inventor.

The gcodes generated for machining based on the cad designs can be found Here

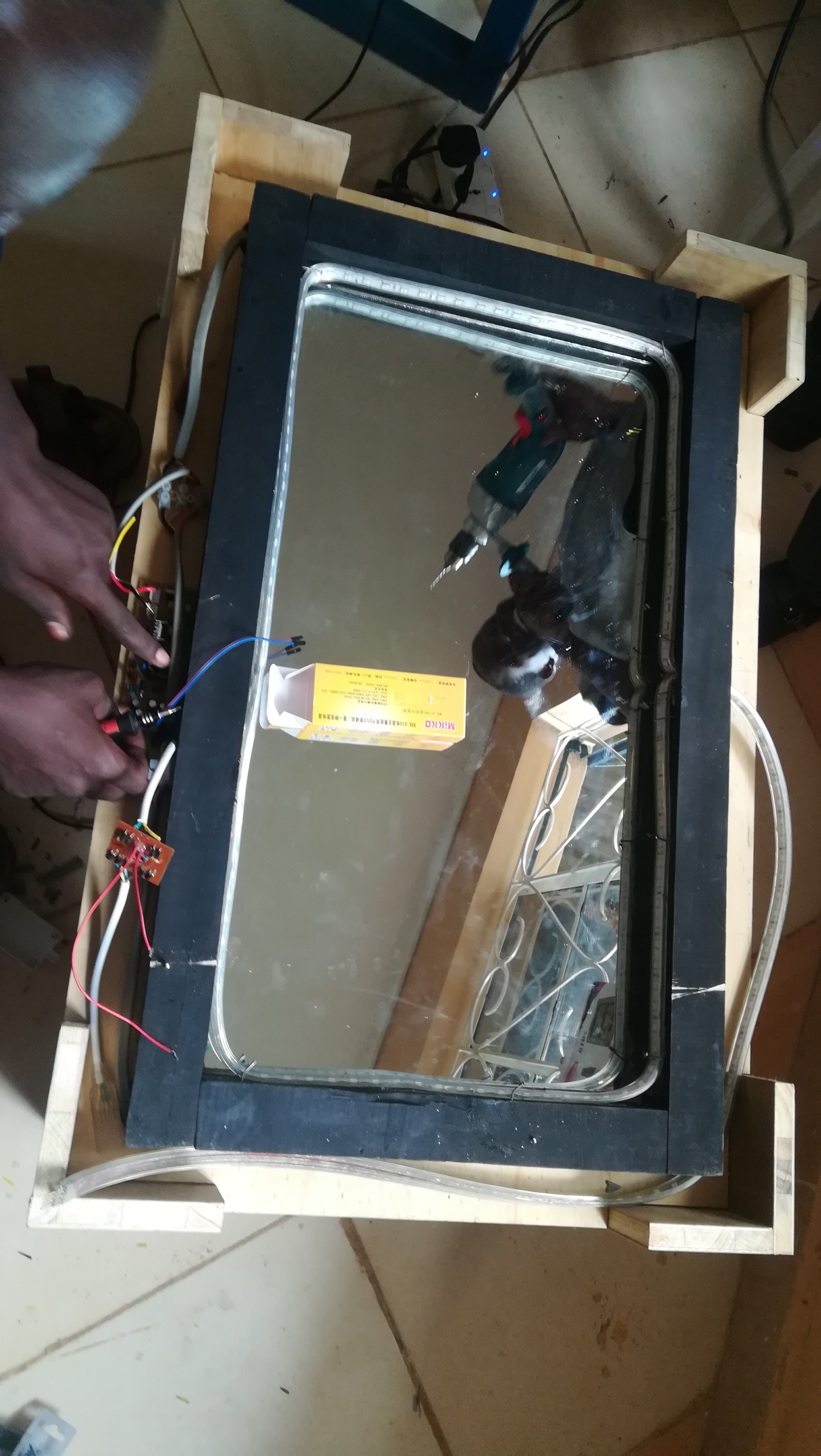

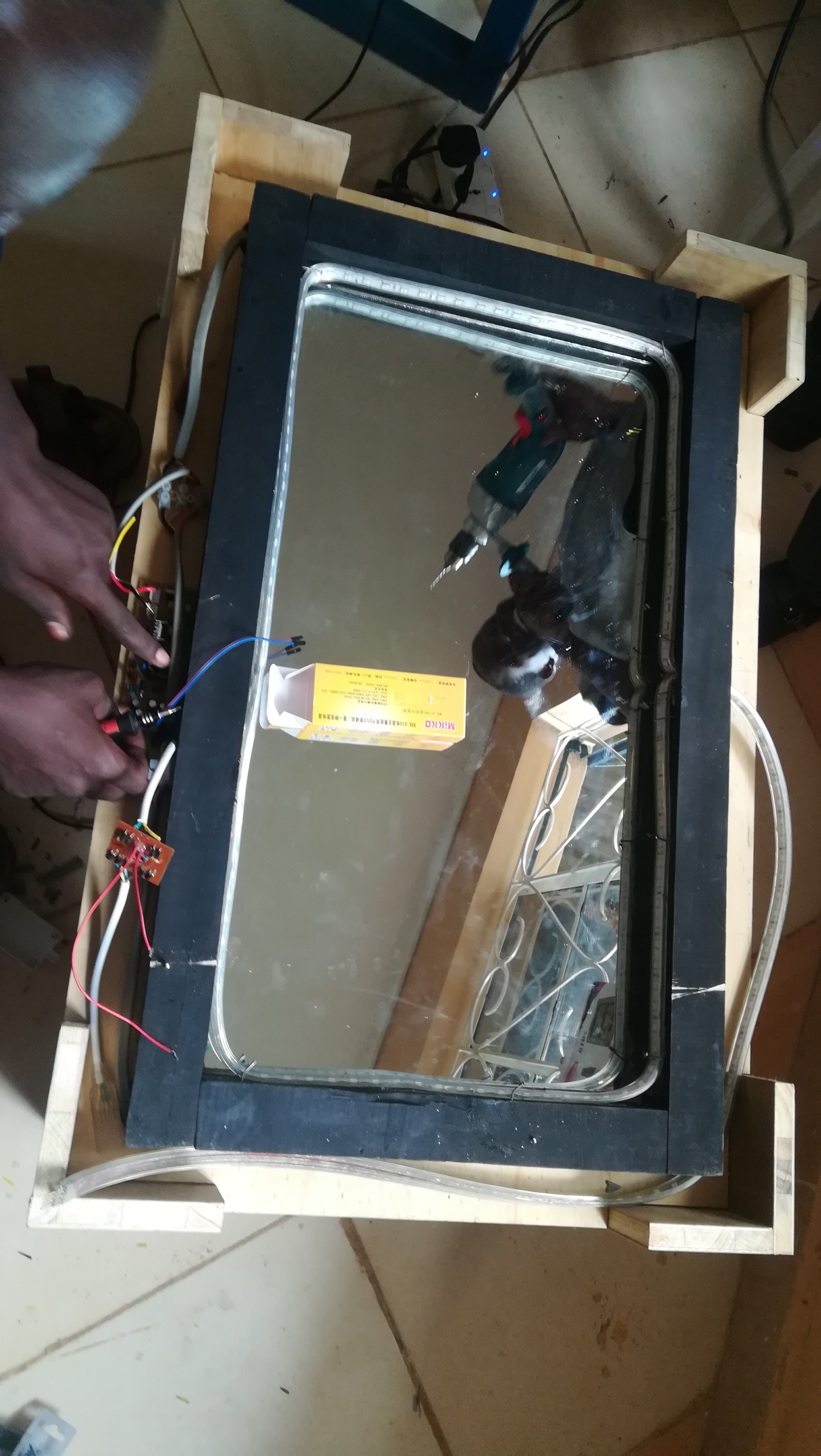

The next stage was assembly i began by assembling the spacer for the mirror and top glass and spray painted it black to increase the Infinity mirror illusion. This is as sown below

The next step involved assembling the legs of the Coffee Table I layed out the parts as shown below then assembled one leg at a time using Screws and a hand drill. Another adjustment I had to make during machining was for the provided hole for the back of the swithc therefore I hard to measure the back part of the swith and alter my design as needed to provide a perfect fit.

The Final Layout is as shown below.

The next stage is to assemble the top and bottom part to the legs as shown

After achieving this the next stage is incorporating the electrical design apart from the board I developed in Week 12 The bill of material for the electrical circuit is as shown below:

- 2.5mm Twin with Earth electrical cable

- AC to DC power module

- Sockets

- AC British Wall Plug

- Led Strip 2.5m

- 20A Connectors

The final board appeared as shown below

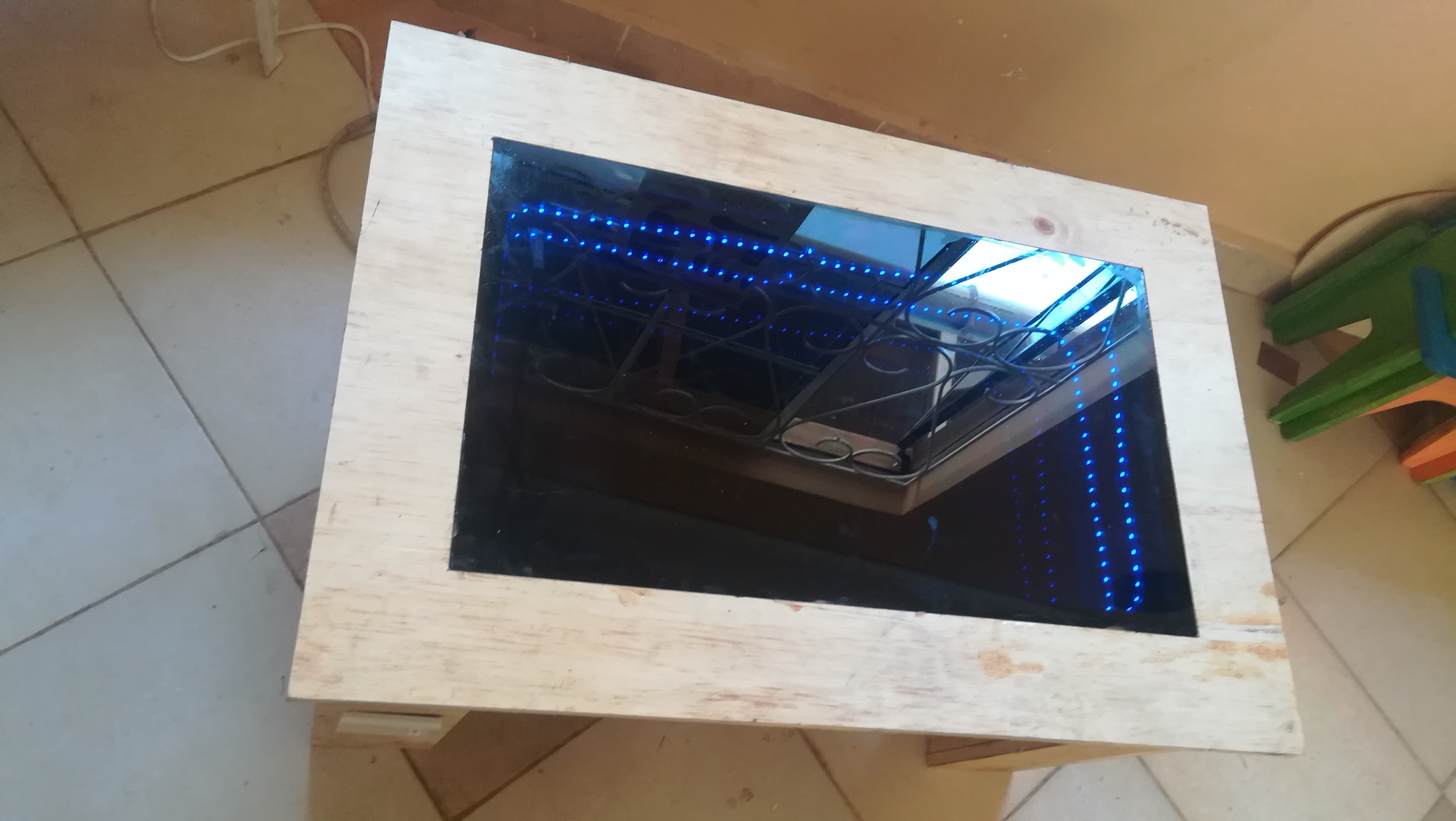

After connecting the components the top layout before complete finishing appeared as shown

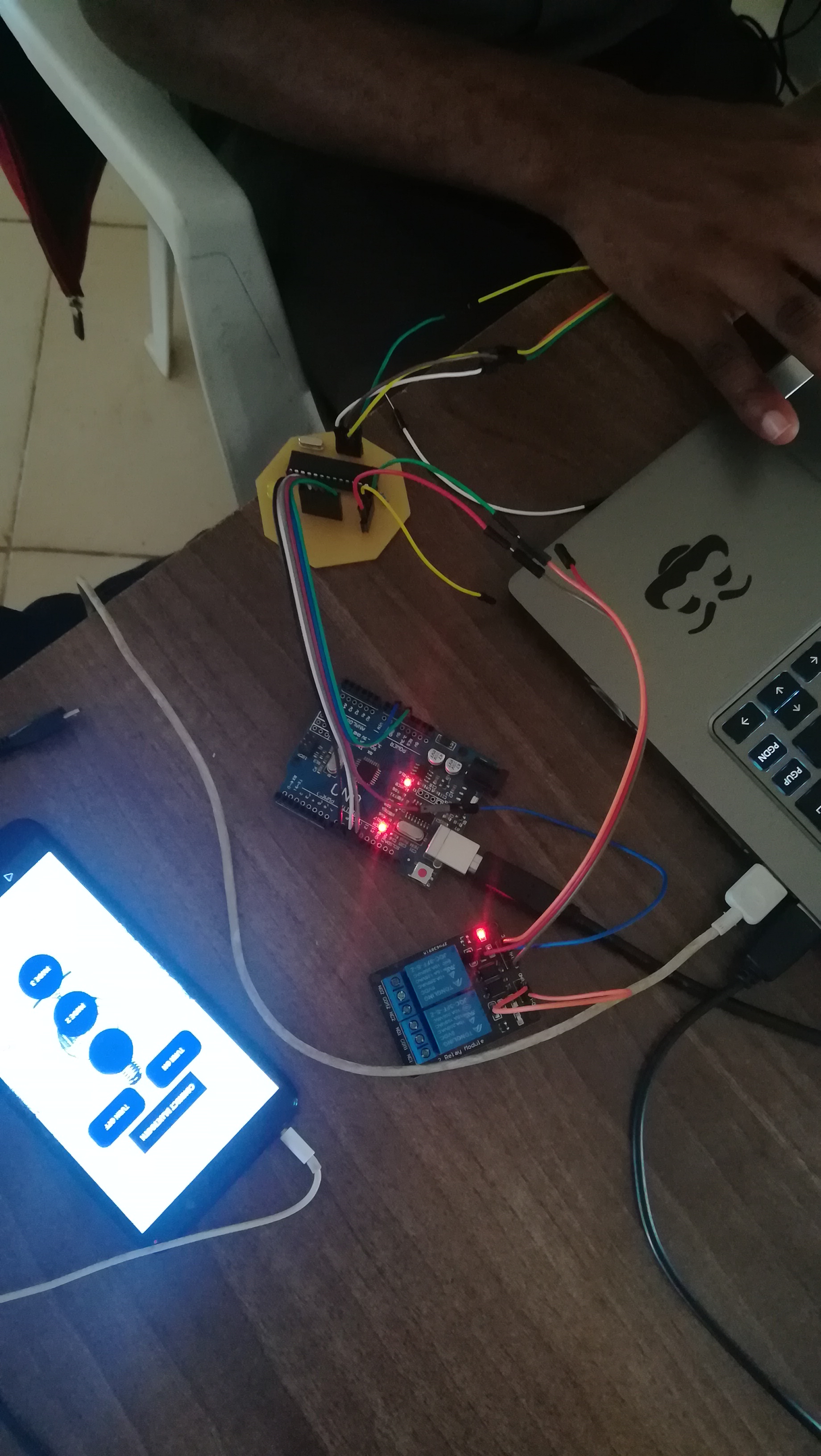

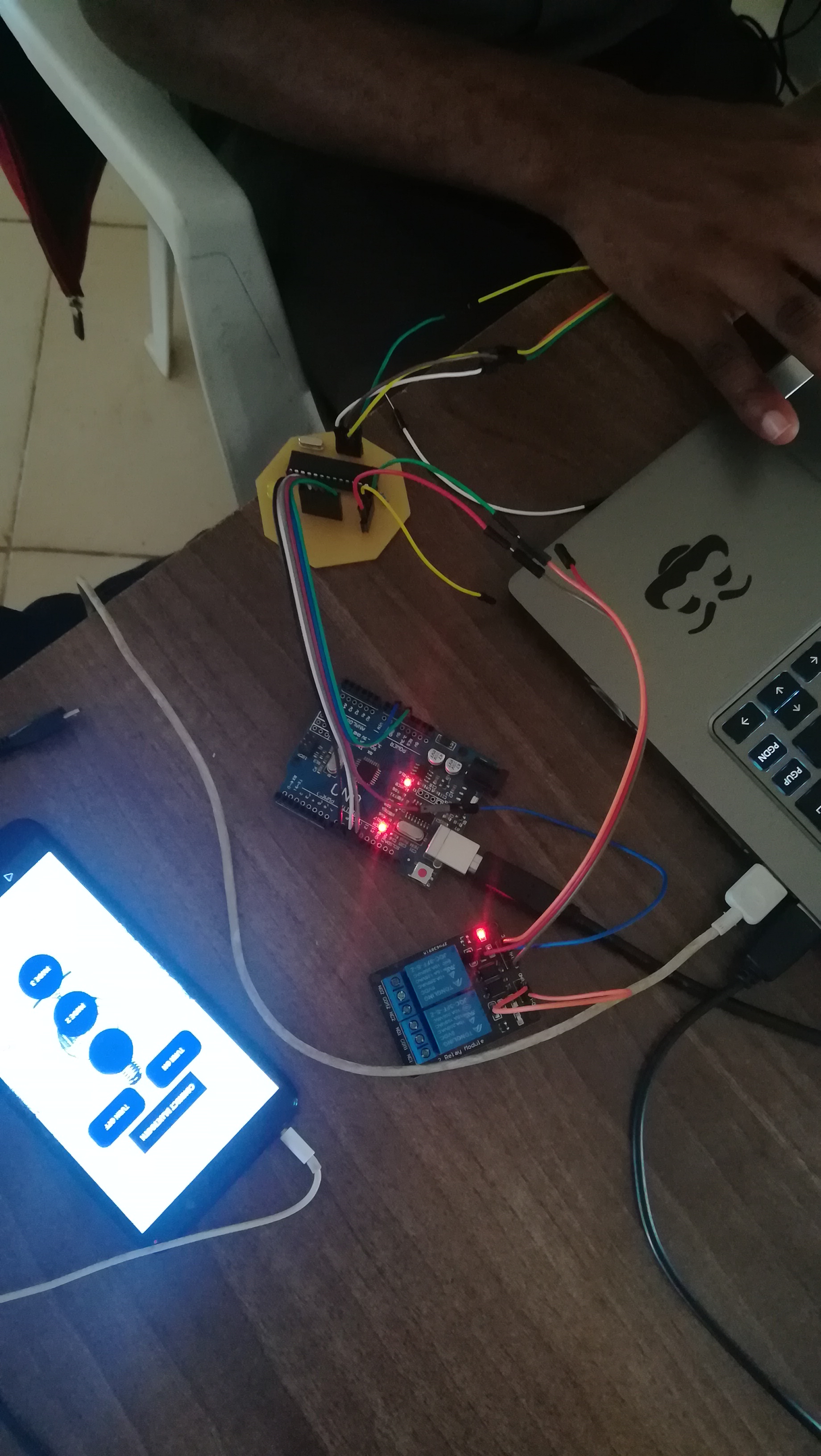

Before proceeding I had to test the seperate components and ensuring they were all working okay before placing them into the coffee table

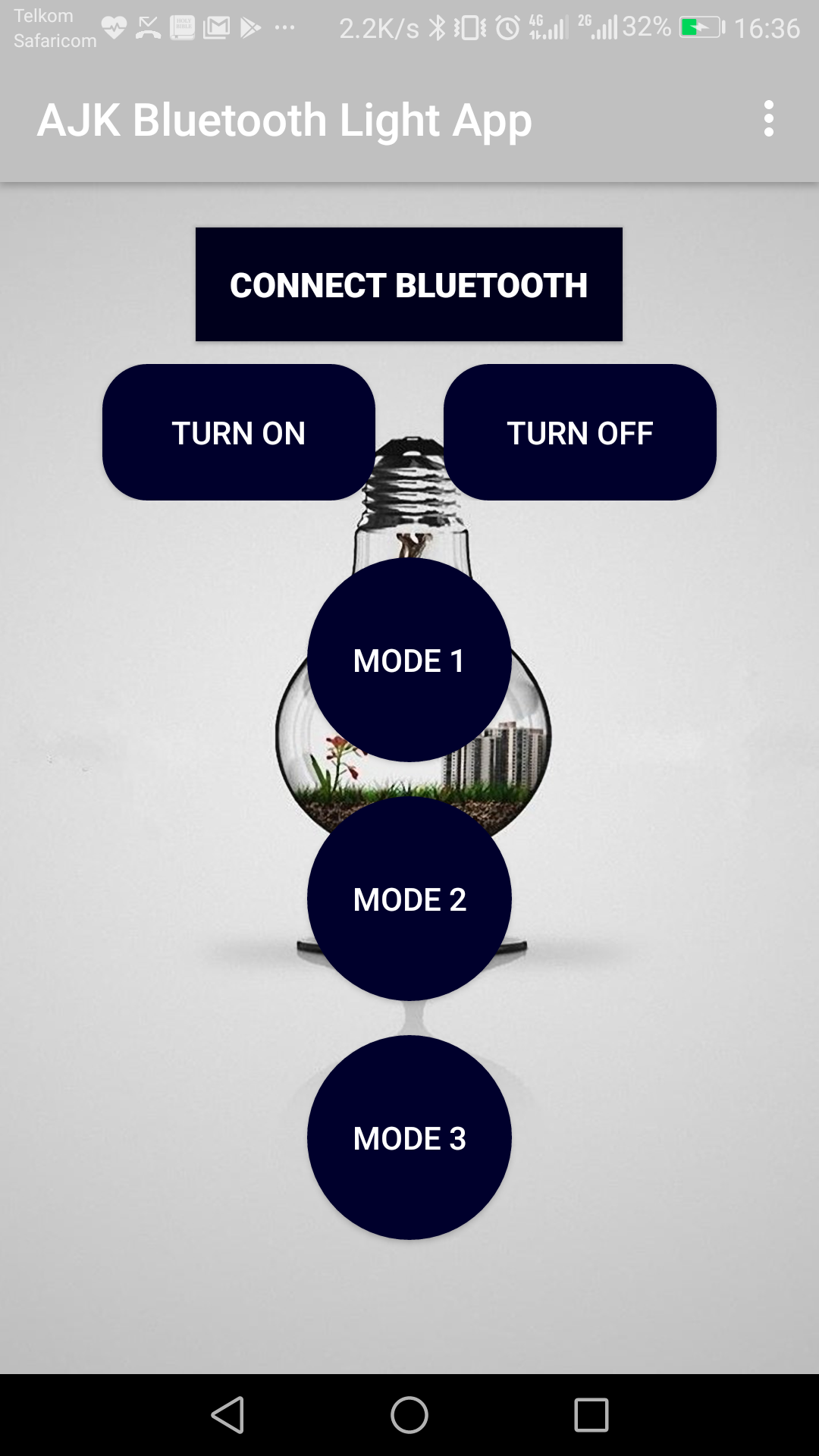

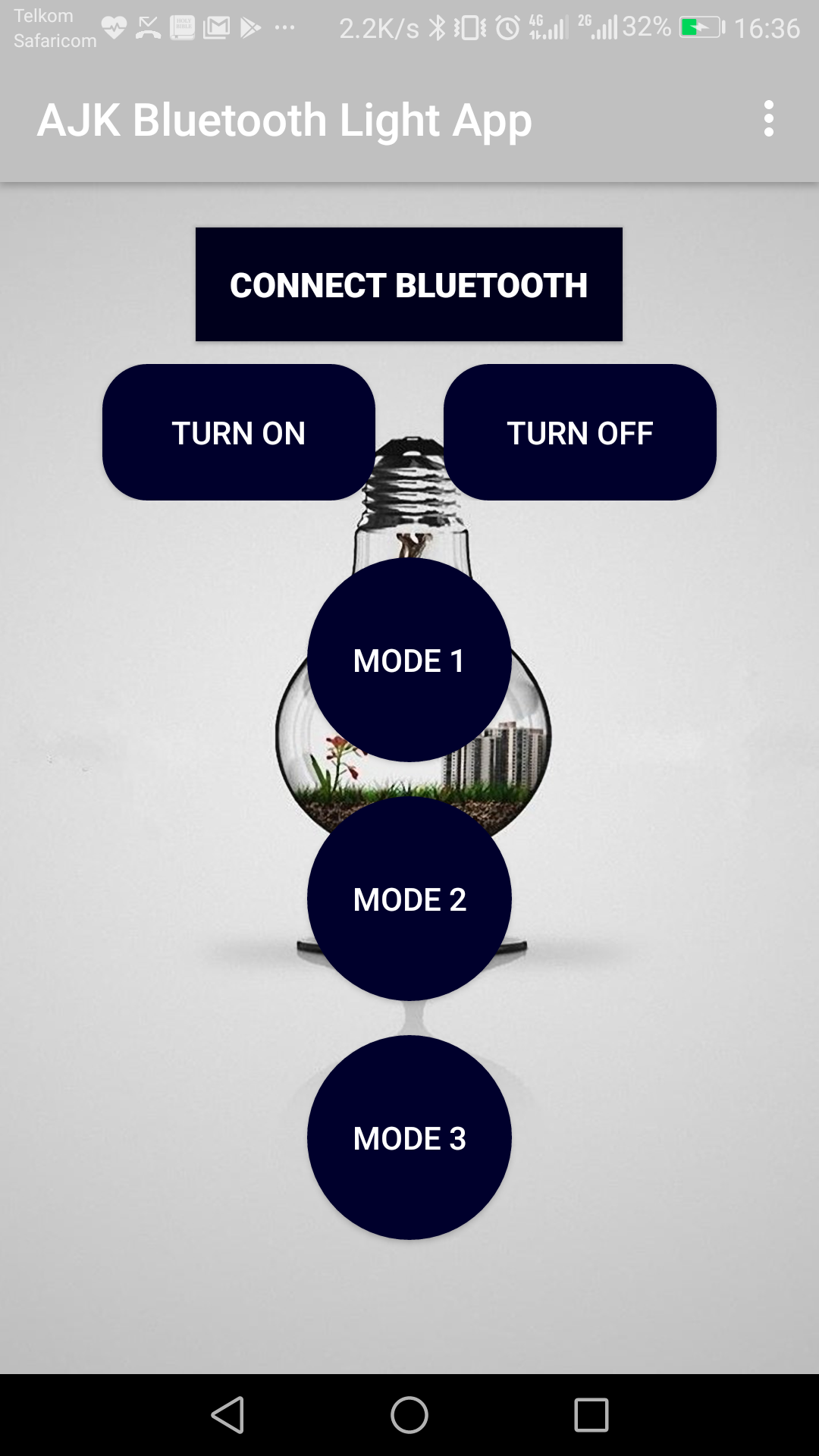

The next stage involved ensuring the interface developed in Week 16 worked as planned

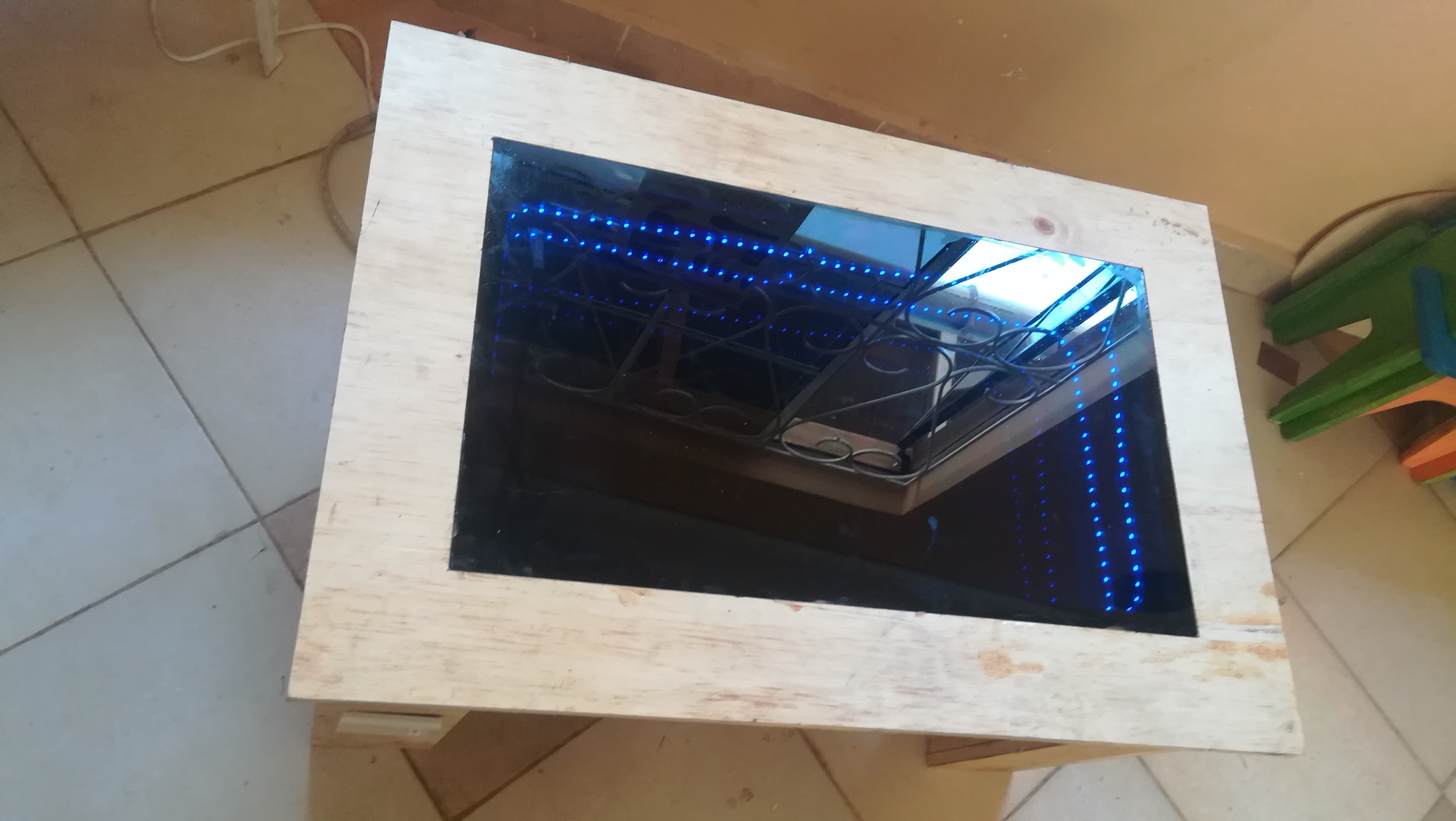

The final project is as shown below

To view the Project Slide click Here

To view the Project Video click Here

Download the CAD files Here

Download the G code files Here

Download the Programming Code files Here

Download the Board Design file Here

Download the Schematic Design file Here

Download the Code File Here

Download the Interface APK master file here

I would like to acknowledge the help of some of my lab partners in achieving this final project such as Derrick Were, Ken Murerwa was also quite instrumental in assisting with developing the interface APK, Abner was also quite helpful in setting the CAM parameters for machining. Martin Oloo provided moral support during the dark days of developing this final project.

I used a creative commons licence to licence my work for this project

This work is licensed under a Creative Commons Attribution 4.0 International License.

The Idea for this table came about when i noticed in many house holds power outlets are either at specific walls of the living room while the sitiing arrangement is different therefore cables run all over when someone wants to charge any device this creates room for accidents easily as one can trip, or plug out a cable forcefully when they trip and either damage the device or the cable.

The Idea for this table came about when i noticed in many house holds power outlets are either at specific walls of the living room while the sitiing arrangement is different therefore cables run all over when someone wants to charge any device this creates room for accidents easily as one can trip, or plug out a cable forcefully when they trip and either damage the device or the cable.

The solution of using the coffee table as an interactive power outlet is because many living rooms have their chairs arranged in a manner to surround the coffee table at the center therefore if each leag of the coffe table had a power outlet and the coffee table had only one cable to the power outlets at the wall chances of accidents are drastically reduced within the household.

Distributing the power outlets will also prevent congestion at the source.

The solution of using the coffee table as an interactive power outlet is because many living rooms have their chairs arranged in a manner to surround the coffee table at the center therefore if each leag of the coffe table had a power outlet and the coffee table had only one cable to the power outlets at the wall chances of accidents are drastically reduced within the household.

Distributing the power outlets will also prevent congestion at the source.