Week15 - Applications & Implications

propose a final project that integrates the range of units covered

CLASS WEB PAGE:

http://academy.cba.mit.edu/classes/applications_implications/index.html

What will it do?

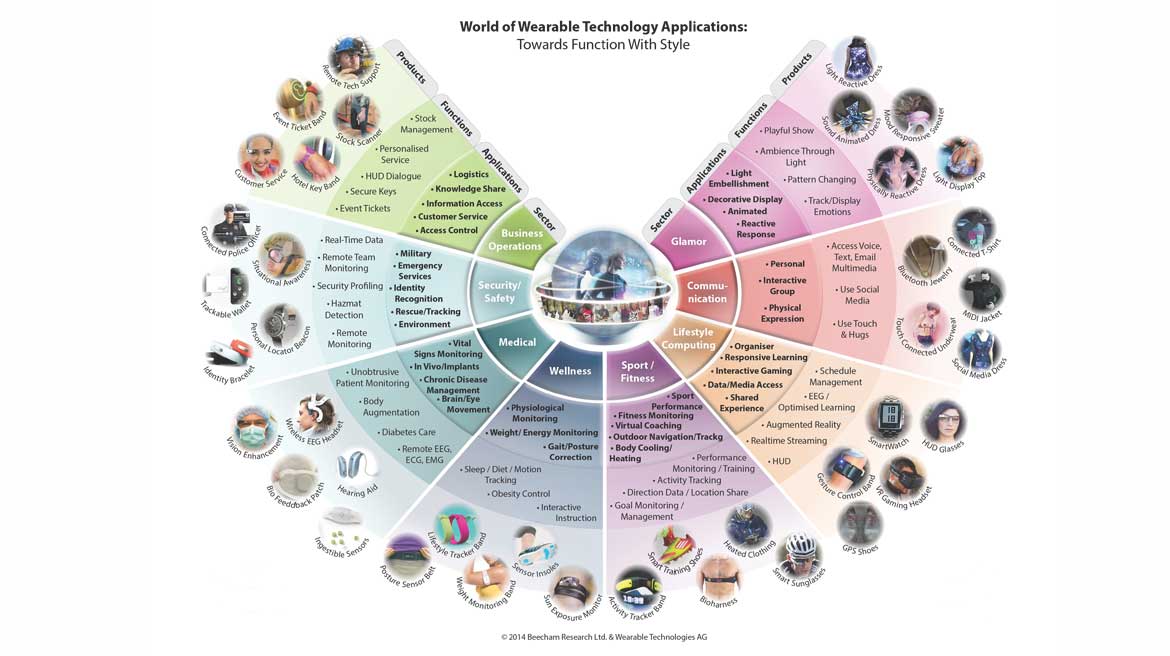

E_Motion is a project about Wearable Computing. A blaze that plays sounds through the user's movement. You can think about it like a second skin that following your movements. Interiorly, the dress will be provided with an electronic circuit controlled by a Fabkit (a PCB produced by me). A flex sensors suited in the fabric sends the signal via Bluetooth to a computer that translates it into a sound output using Processing and a software like Pro Tools. The project comes from the idea I have to make a little show of performative art in the future. So E_Motion should be the first prototype of a series of "dresses scene" made by myself.

Who's done what beforehand?

On the web we can find many examples of fashion design. 'Here' one of the most famous. About interactive fabrics there is a great boom and the majority of the work relates to the interaction with the light but also with the sound start to be some experiments. 'This' and 'This' are two examples near to my idea of my project.

What Materials and Components will be made and Where will they come from?

E_Motion will be made of thin elastic neoprene (3 mm) that allows us to have a better control of the intensity and duration of sound related to the body movement. In the inner part will be placed the removable electronic circuit for washing the dress. The Board has a support in PLA printed with the 3D print Machine

The neoprene fabric will be retrieved from a local retailer in Frosinone. Electronics components will be purchased on the web.

How much will it cost?

The total cost of the project will be more or less 110 euro (120 USD).

For the dress I need more or less 6 mq of Neoprene Fabric for about 50 Euro, 1 zipper for about 5 euro for meter, 1 spool of trhead sewing for about 2 euro.

The price for Conductive Rubber Cord Stretch is 8.92 euro for 1 meter.

A rechargeable lithium polymer battery cost is around 12 euro.

The support of the board will be print about in 30' for a total of 12 euro (2 euro for the support and 10 euro for the use of machine).

The milling of the board is about 15 euro and the price for the components of the Board is around 5.50 euro:

- ATMEGA 328P Atmel 1.80 euro

- CAPACITOR 0.1 uf 0.015 euro

- CAPACITOR 10 uf 0.06 euro

- SMT PCB BUTTON 0.27 euro

- RESONATOR 8 Mz 0.17 euro

- RESISTOR 10 K 0.09 euro

- RESISTOR 499 Ω 0.04 euro

- RED LED SMD 1.8 V 0.30 euro

- PIN HEADER (various) 2.00 euro

What parts and systems will be made and What process will be used?

Starting from an hand sketch I'll design a 3D Model of the dress made in Neoprene that will be cut by Laser Machine. The seams will made by hand or machine depending on the type.

The Electronic Board will made with the Roland SRM Milling Machine and all components will solder by me. The support for the Board will made with the 3D Print Machine.

what tasks need to be completed?

The Concept of the Project has been defined and I designed the jacket to be milled. The Circuit Scheme was already designed and I milled and welded a new Fabkit. I have to test and program the board and write the code. I have to mill the Neoprene Fabric. Sewn the jacket, I have to print the support of the board and fix the Circuit to connect with the PC. I need to do the Interface to obtain the sound output.

What questions need to be answered?

I'll need to know what will be the right thickness of the fabric (Neoprene) to cut it simply without damages and having never tried this material with the laser machine I don't know the right parameters of cutting and engrave for it.

I will have to test the correct position of the stretch sensors to have the optimal input value and at last I'll have to study how to translate my feedback data in sound.

what is the schedule?

I decided to subdivide my work in three weeks:

1st: Dress Design and Measuraments, the purchase of all materials and Circuit Design.

2nd: Fabric Cutting, Circuit Production and Testing of it, Interface and Sound output.

3rd: Tests and Solutions of possible problems.

How will it be evaluated?

New technologies have radically changed the society and with it the art world. In the performing arts we can see a great development about the Interaction between the body and mechanical or informatic systems. Through an Interface it's possible obtain, for example, sound or light effects directly connected to the body. The Wearable project E_Motion is placed exactly in this sphere of Interaction Design to give a contribution to Performing Arts. Built a first prototype,hopefully working, it will possible continue working on the project and develop different solutions of it, both aesthetic and sound effect.

In practice on my mind there is the target to obtain a sound as sweet as the violin... but if it will make noise it is already a success!!!