Molding and Casting

Design

The purpose of the week is design a 3D mold, machine it, and cast parts from it.

In Annecy the trashes for recycled items are locked, you need a triangular key to open them. so I decided to create a mold for this triangular key. The 2 parts were created under Rhino and export as STL file:

The first part of the mold is used to cast the mold of the symetric part of the piece.

The second part of the mold is used to cast the mold of the triangular part of the piece.

Machining the molds

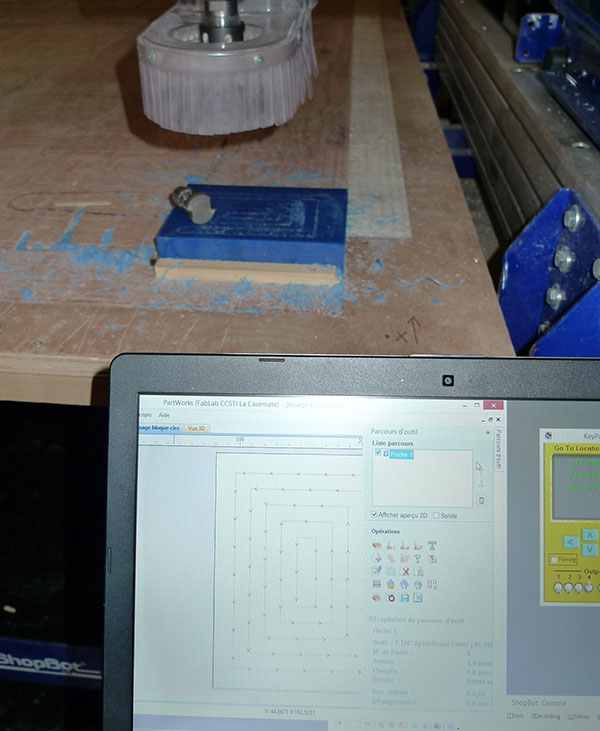

The Modela is in used so I decided to mill the mold using the Shopbot in order to practice PathWorks3D

I will use a block of parafine which was recycled, so the Top surface is not really regular and has some bubbles. I will use pathWorks(2D) to clean this surface by creating a 'poche' which cover the whole surface:

Then under PartWorks 3D for each stl file you have basically 4 step:

1: set a correct Size and Position of your STL in order to mill it from the top.

2: set a correct Size and Position of parafine block, and the position of the job into it

3: define path / tool /speed for the Rough Milling.

4: define path / tool /speed for the Finishing.

unfortunatly when the block of parafine was recycled, lots of bubbles were stuck near the top surface and some are still here after the machining. but I am lucky because it s not the important part of the mold.

Casting the Molds

I used the Smooth-On Mold Star 16 FAST to cast the mold. First I filled the molds with water and I put the water in a glass just to evaluate the quantity of product necessary.With this product the propotion is 1A for 1B.Then I cast the mix into the molds and put them under Vaccum air system to get ride of the small bubbles

Then I have to cast a second time the symetric part.

Casting the final object

1: Prepare molds with "Universal Mold Release

2: Putting all molds together

3: I used "SmoothCast325" which is liquid plasic, perfect for pouring into rubber molds .

4: Then Put it under the Vaccum air system to get ride of the small bubbles.

3: After 15 Min release the item and remove extra plastic with a cutter.

all the shortcoming are due recycled block of parafine,not from the casting.

all the shortcoming are due recycled block of parafine,not from the casting.

you can find the design files on my

github repository :![]()