Composites

Composites

The purpose of the week is to design and make a 3D mold, and produce a fiber composite part in it

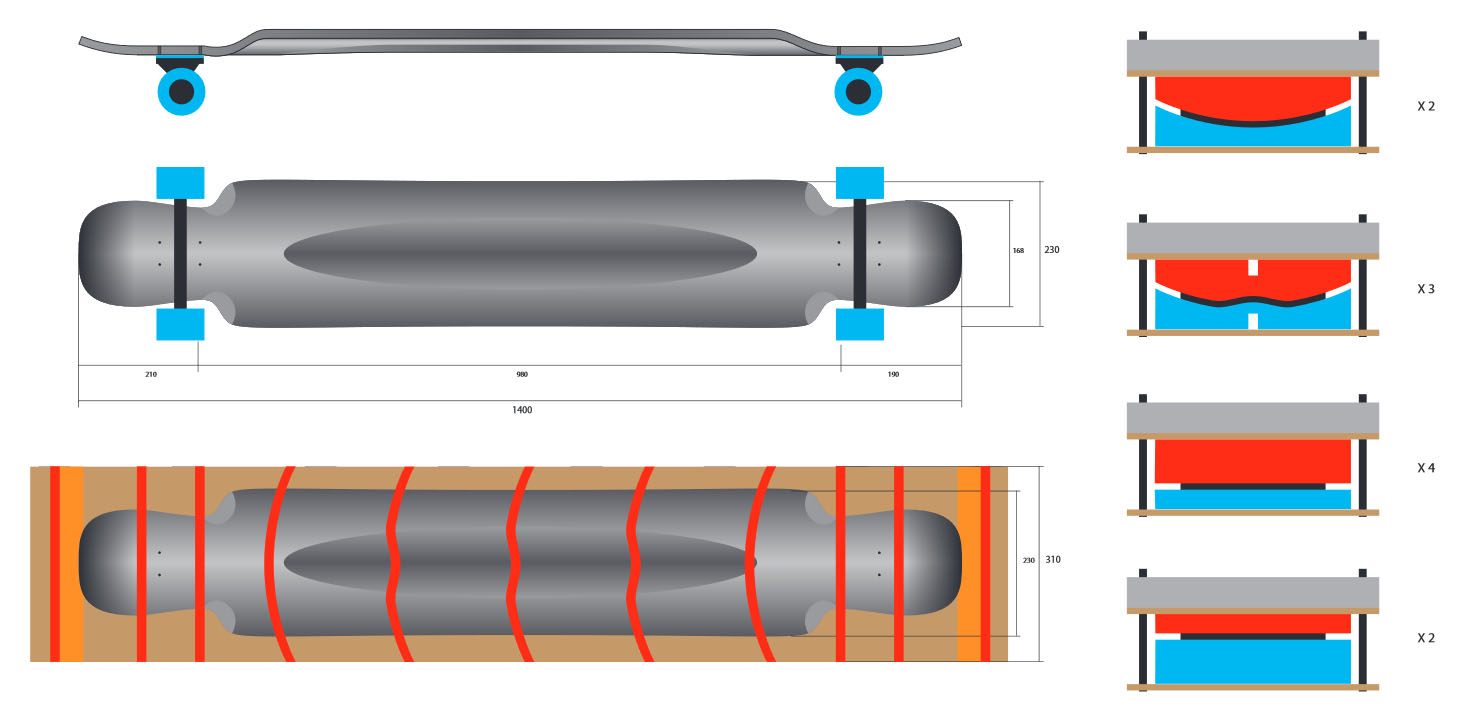

I decided to create a positive and negative mold for a long board.

The design was done under Adobe Illustrator :

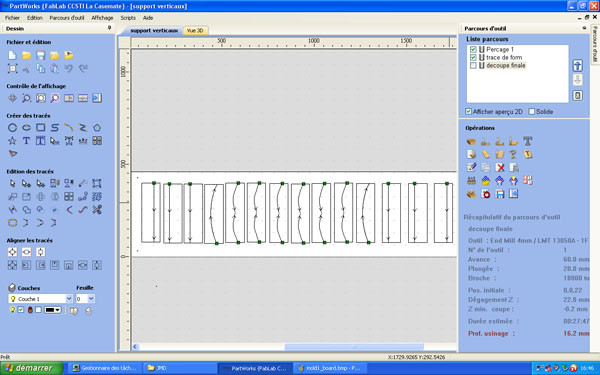

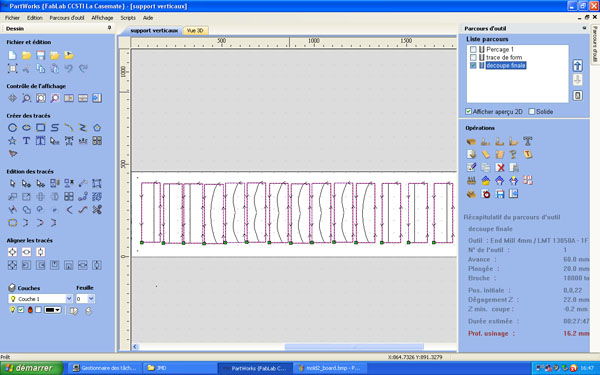

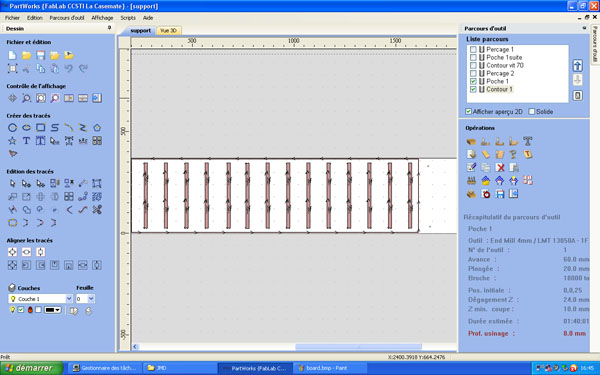

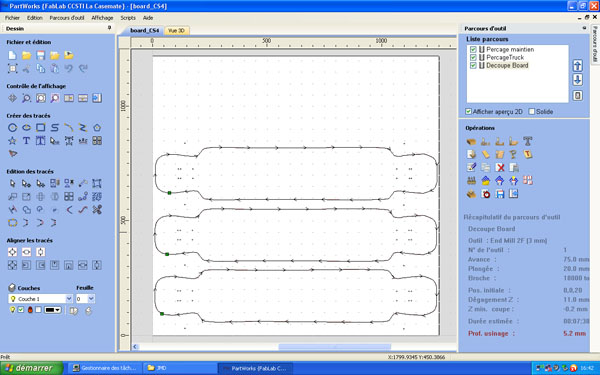

The toolPath was create under PathWork

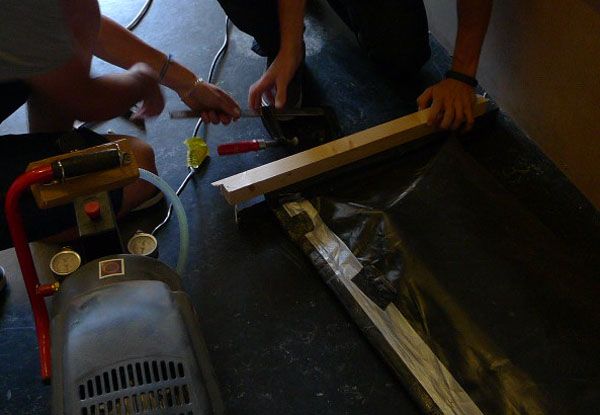

And then the machining:

Safety First during machining.

Safety First during machining.

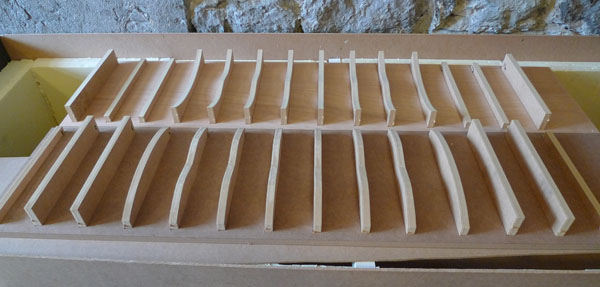

Machining and Assembing Done:

Cutting the board

First test:

Unfortunately the thickness of the wood used was too big (5 MM) and two plates have been broken. There was no more available wood with 140 cm length and small thickness.

So for the validation of the composite section, we decide to use small part of wood by making a normal skateboard.

The wood (3mm) was cut using Laser cutting.

I will use natural fiber in order to test it.

Following the different steps:

-First using the plank as model,cut the fiber :We will use 3 board planks and two fiber layers,one in the direction of the fiber, one perpendicular.

-Prepare the workspace: put a plastic on the mold (the resin can't fix on it), be sure to have all the parts around.

- Mix the Resin and the Hardener: 2 volumes of resin for one volume of hardener.

-Spread the resin on the first plank of wood.

-Remove the surplus.

-Put the board correctly to the mold.

-Place the natural fiber and remove the bubbles.

-Spread the resin with the spatula in the direction of the fiber

Composit from JM Durney on Vimeo.

-Spread mix on second plank and make the sandwich.

-Repeat the procedure with the second natural fiber

-Put the plastic over the board and Put in the vaccum bag

-Remove the air and ensure that the board fit the mold:

VaccumBag from JM Durney on Vimeo.

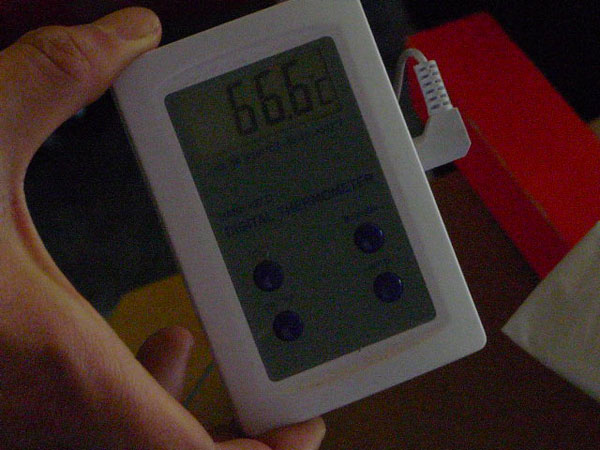

-Then put whole stuff in the oven, with temp it will take about 40 min.

-After 40 Min exit from oven and vaccum bag. It's still hot, so use this time to remove the surplus.

The advantage of the natural fiber is that you can use a cutter when it's still hot.

-After cleanup and sandpaper

-Test resistance : 80kg

you can find the design files of long board and the mold on my

github repository :![]()