This week, we got introduced to various digital fabrication cutting tools, and assembly techniques, mechanisms and methods which allow for increased effciency during fabrication and assembly. The three main tools available to complete the assignment were the Epilog laser-cutter, Roland Vinyl-cutter and the Roland Moldela.

Each of the machine has its own set of rules in terms of operation, safety and maintenance. The lecture notes can be found here.

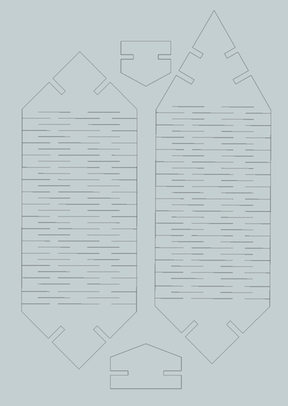

The aim of this weeks assignment is to use the computer -controlled technology to produce a press-fit construction kit using corrugated cardboard. No glue or tape is to be used.

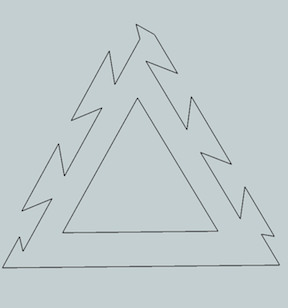

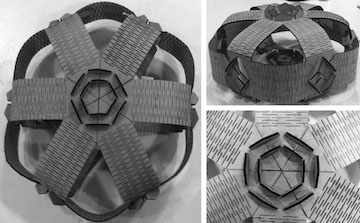

Bendable/ foldable hard surface have always been interesting to me so I decided to make a modular ornament and incoporate kerfing in my design.

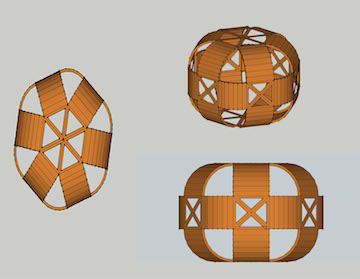

I spent a large amount of time designing and exploring. I used Sketchup to design a 3D model. To make cardboard kerf, I had to design grid of holes or spaces for the machine to take out. Half-way through, I realized that sketch-up wasn't a good tool for making grids, its a good visualisation/ conecpt- developing software..But it was too late to redo the design using different software, so i had to make it work the hard way.

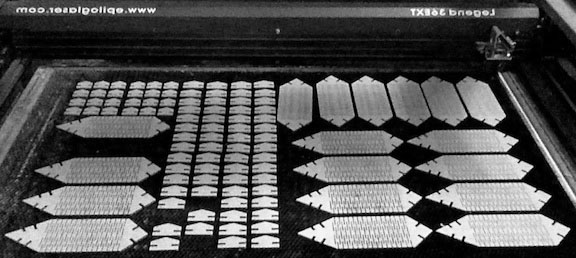

The structure is to be made of 18 pieces.

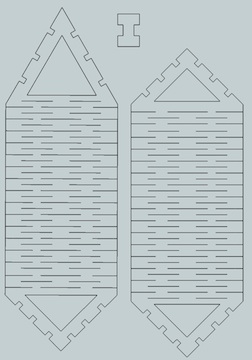

The Epilog laser-cutter the best fabrication tool in this case. I set the speed and the power of the laser to 50% by 50%. The challenge here was to try and fit all the pieces in the machine in order to cut in one go. The maximum dimension of the cardboard to fit the machine is 60cms x 90cms.

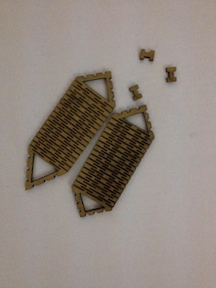

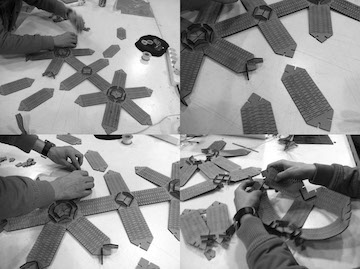

The biggest challenge was to figure out how I'm going to connect the pieces (joints and hinges). I came up with 3 different designs. The third attempt was the most successful.

The product wasn't stiff enough and was really hard to assemble, hence, I used tape to aid assembly.

The final result wasn't satisfying. Cardboard was challenging to work with. I will have to experiment with different material such as wood and acrylic for kerfing. I also have to figure out a better system to connect the joints. Maybe increase the friction in the joints to make it stiffer. Expermentation is key to success.

Click here to download the 3D Model Files.

Click here to download the 2D cutting Files.